Aconity3D GmbH Launches Additive Series Production

Aconity3D GmbH Launches Additive Manufacturing (AM) Series Production.

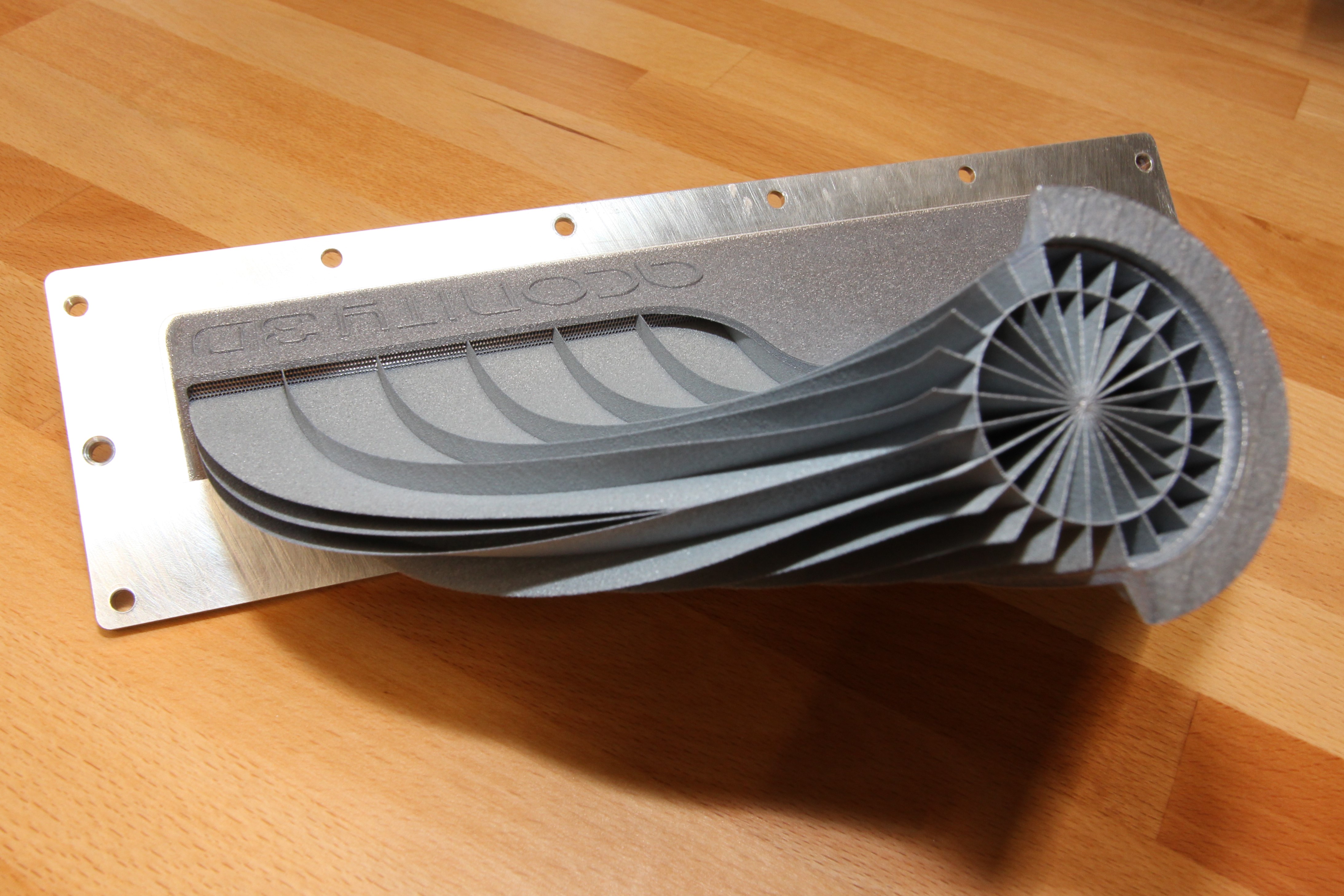

The illustrated part shows a gas guiding geometry which is applied for the fume extraction unit of Aconity3D metal printers. For 3D printing of metals a homogenous fume extraction represents a precondition for manufacturing high quality parts with minimum variation at industrial standards. Using Aconity’s own 3D printers for series manufacturing of these AM parts yields a drastical improvement of the part performance while keeping manufacturing costs low.

At this, part performance was improved by using very filigree gas guiding structures, which barely interfere with the overall cross section of the duct. Furthermore, an extremely fine lattice structure was incorporated at the gas outlet for a further homogenization of the gas flow.

Cost reduction was achieved by applying optimized single line scanning strategies for the filigree gas guiding structures while applying a part design which exploits support free build-up onto Aluminum preforms. The absense of support structures alongside with the applied preforms allows for immediate use of the built parts without any further post processing.